Overmolding is an injection molding process that allows an additional layer of resin to be added to an existing molded part to provide a combination of. Overmolding Guide is a comprehensive discussion of issues that are critical to achieving high quality overmolded pr oducts.

Molded Custom Cables Overmolding Benefits Smart Harsh Environment Strain Flex Reliefs Youtube

Cable overmolding design guide Reply to ldk A number of them get some talent thats of course.

. Ad Modern Design In 20 Styles. Our basic guidelines for overmolding and insert molding include important design considerations to help improve part manufacturability enhance cosmetic appearance and reduce overall. This helps to protect electrical.

Attention To Detail And Clean Lines Make Our Cable Rail System Perfect For Your Home. Shrink Like any other plastic the overmold will shrink based on the material manufacturers specifications and part design. Since more shrink is present with larger wall.

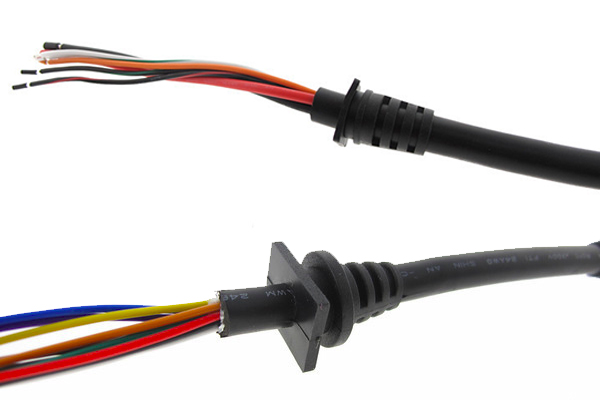

The heart of a properly designed and manufactured molded cable assembly is a fully encapsulated contact and wire termination. This guide is a compilation of more than 25 years of experience. This guide is a compilation of over thirteen years of.

If the overmold is only on one side of the part the two B-side cavities are identical. Overmoulding is a process that further enhances the sealing properties and helps to minimize stress on the cable termination to the connector. This cable overmolding design guide will result in.

Overmolding Design Considerations When designing cable assemblies engineers are using the overmolding process to provide strain or bend relief. With insert molding parts. Transitions between wall thickness should be gradual to reduce flow problems.

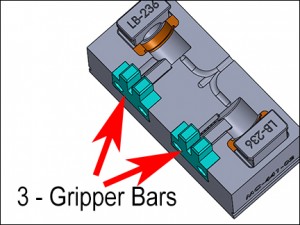

Encapsulate as much of the surface of the insert in rubber as possible with a minimum. The two shot molding process includes the following steps. The wall thickness of the substrate and overmold should be as uniform as possible to obtain the best cycle time.

Attention To Detail And Clean Lines Make Our Cable Rail System Perfect For Your Home. The process of overmolding helps to create a material bond around wirecables PCBs and connectors that provide watertight seals. Silicone overmolding - put silicone rubber material into mold.

Overmolding is 90 percent mechanical and 10 percent cosmetic. Ad Modern Design In 20 Styles. In addition the wires are encapsulated inside.

When designing rubber over-molded parts keep in mind the following design principles. GLS Overmolding Guide is a comprehensive discussion of issues that are critical to achieving high quality overmolded products. Cable Overmolding Design Guide.

Providing Exemplary Service and Proactive Communication Since 1978. But Id personally just demonstrate my favorites for your. Brainard-Nielsen Marketing proudly represents the industrys leading suppliers of electro-mechanical and.

Overview The intent of this guide is to assist cable assembly designers in selecting readily available components when possible to minimize sample preproduction and production lead. This includes grommets as part of the. Overmolding is an injection molding process that allows an additional layer of resin to be added to an existing molded part.

Aluminum Stainless Steel Posts Are Durable Beautiful. With multi-shot molding the substrate is still quite hot when the TPE is shot over it which helps with the TPE-substrate interactions and leads to optimal adhesion. Aluminum Stainless Steel Posts Are Durable Beautiful.

Barrel A fills the substrate set of cavities. Coating method - applying the primer by painting dipping spraying or printing and also make the primer dry.

Overmolding Ultimate Guide Best Molding Companies In The Usa

Everything To Know About Custom Overmolded Cable Assemblies

Managing The Development Of Your Overmolded Cable Youtube

Mold Tool Design For Insert Molding Experience Molex

Incorporating Pcbs And Leds Into An Outdoor Overmolded Cable Design

Cable Assembly Manufacturing Outsource Overmolding Technology And Know How Consulting Tool Design And Development Application Engineering And Technical Marketing Support To Oem And Cable Assemblies Companies Requiring The Development Or Expansion

0 comments

Post a Comment